Vacuum Lifters

What is a Vacuum Lift?

A vacuum lifter is a lifting device that uses suction power to grip and move goods of different shapes and sizes. By reducing manual lifting, vacuum lifters improve ergonomics, increase productivity, and minimise product damage.

Why choose vacuum lifting equipment?

- Handle loads from small boxes to large panels. Our vacuum lifters have lifting capacity up to 270 kg.

- Secure grip on loads without damaging surfaces.

- Ergonomic and safe operation. Reduces employee strain and injuries.

- Fast, efficient workflows in warehouses and factories.

- Flexible suction tools for many materials.

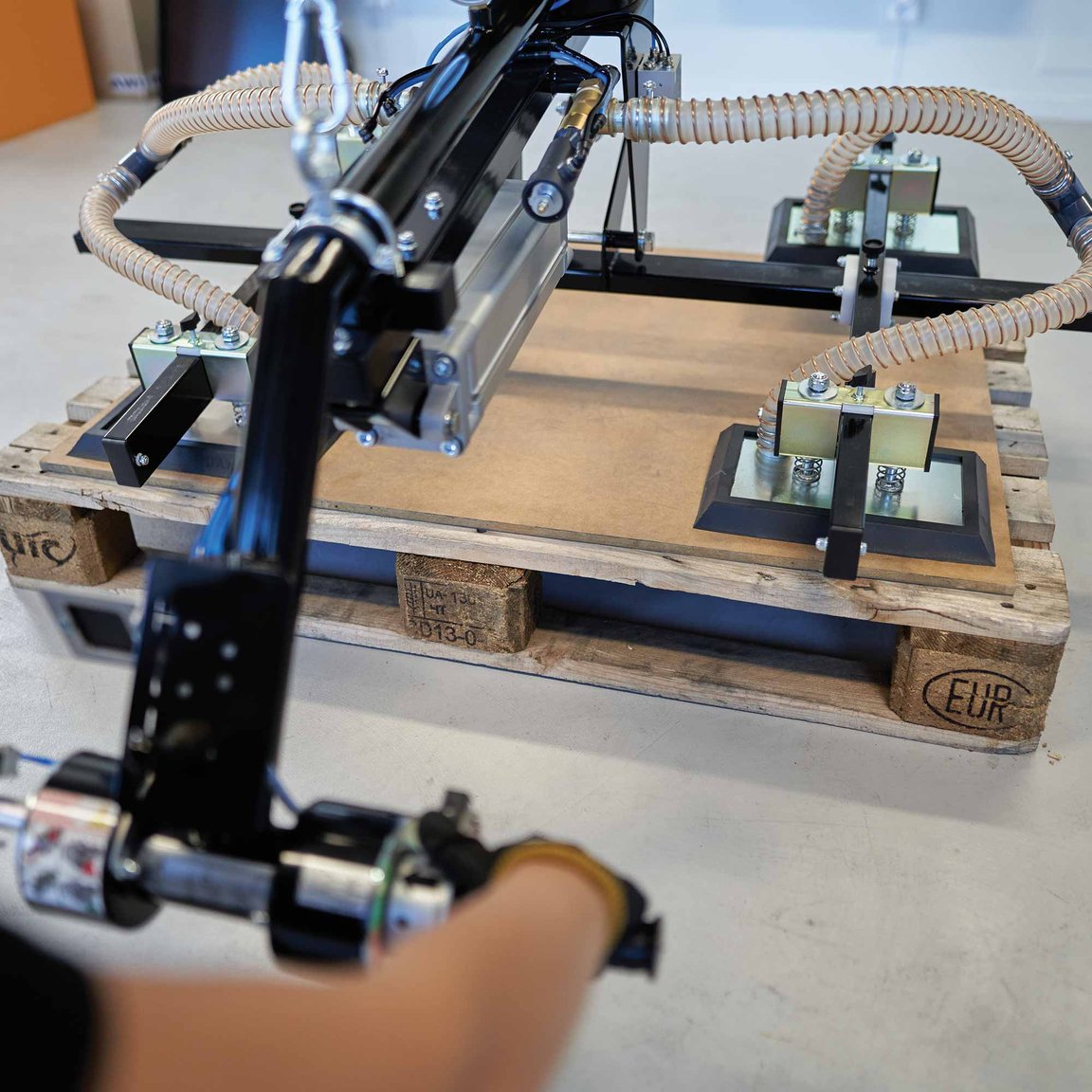

See TAWI vacuum lifters in action

See how our vacuum lifters make lifting boxes, sacks and various goods both ergonomic and efficient. This demo shows how the vacuum lifters work and how operators can handle loads quickly and safely with minimal effort.

Ergonomic & efficient everyday lifting

Our vacuum lifters are robust and reliable tools that make manual handling of loads safer and more efficient.

TAWI vacuum lifters allow operators to lift up to 270 kilos without effort. Giving everyone the power to lift increases workforce flexibility, making it easy for employees to switch between work stations. Vacuum lifting equipment is extremely versatile, handling everything from simple boxes to complicated car components. Add a quick coupling and you can use the same vacuum lift for more than one application, smoothly switching between different suction feet.

How a Vacuum Lifter Works

- Creates suction: A vacuum pump forms an airtight seal between the suction cups and the load.

- Lifts smoothly: The lift tube raises or lowers the load with controlled air pressure.

- Easy control: Operators move, position, and release goods using a simple ergonomic handle.

Our Vacuum Lifter Portfolio - and how to pick the right one

Choosing the right vacuum lifting equipment depends on your goods, weight, speed, and workflow. Here's a quick guide:

Lifter Type

Best For / Use Cases

Key Strengths / Differentiators

When to Choose

General handling in factories, warehouses, food, pharma, & packaging. Lifting items such as boxes, sacks and components.

High capacity (up to 270 kg), two-handed stable operation, customisable suction tools. Various handle options e.g. for lifting above shoulder height.

When you want flexibility, stability and customisation.

High-speed palletising from conveyors, packaging lines, warehousing. Lifting boxes and baggage.

One-handed joystick control, fast grip and release, lightweight loads (up to 65 kg), grip items from top or side.

When speed, repeatability and throughput are key.

Large panels, sheets, slabs of wood, metal, glass, laminates.

Designed for large, flat goods: tilt/incline, multiple suction feet, safe handling of loads up to 180 kg (or more, depending on config).

When your main challenge is handling panels, sheets, large flat materials.

Overview

Throughput needs:

- Fast pick & place → High Frequency

- Flexible handling & stability → Multifunctional

Weight capacity:

- Up to 270 kg → Multifunctional

- Lightweight (up to 65 kg) → High Frequency

- Large surfaces (panels up to 180 kg+) → Panel Lifter

Not sure which solution is right for you? Our experts help you match the right vacuum lifter to your load and workflow.

Frequently Asked Questions about Vacuum Lifters

What is a vacuum lifter used for?

A vacuum lifter is used to safely grip and move loads such as boxes, sacks, drums, panels, and sheets. It reduces manual strain and makes handling faster and more ergonomic.

How do vacuum lifters work?

Vacuum lifters use suction cups connected to a vacuum pump to create a strong, airtight grip on the load. A lift tube raises or lowers the object while the operator controls everything from a simple handle. The operator can then lift, move, rotate, or tilt the object with minimal effort. To set the load down safely, simply lower the load to desired location and break the vacuum by pressing the release on the handle.

What are the main parts of a vacuum lift?

Vacuum Pump or Ejector – Generates the vacuum pressure that powers the lifter.

Suction Cup(s) – Flexible cups that create an airtight seal on the surface of the load. Different shapes and sizes are available for boxes, bags, panels, and other materials.

Lift Tube – A vertical tube that contracts and extends using vacuum power, allowing the operator to raise and lower the load effortlessly.

Control Handle – The operator’s interface, used to grip, release, lift, or lower the load with simple and ergonomic hand control.

Mounting System – The lifter is usually suspended from a crane, jib arm, or overhead rail system to give reach and flexibility across the workspace.

What material can vacuum lifters handle?

TAWI vacuum lifters can handle cardboard boxes, paper or plastic sacks, wooden boards, glass sheets, metal panels, and many other materials. With the right suction tool, even fragile goods can be lifted without damage.

Are vacuum lifters safe for operators?

Yes. By reducing heavy manual lifting, vacuum lifters lower the risk of injuries, strains, and long-term musculoskeletal issues. They are designed to meet strict safety standards and ensure secure load handling.

Which TAWI vacuum lifter should I choose?

For flexible handling of various loads → Multifunctional Vacuum Lifter

For fast-paced, repetitive lifting of boxes or baggage → High Frequency Vacuum Lifter

For lifting of large panels or sheets → Panel Lifter