Pick and move reels from pallets with smart reel lifting equipment

Depending on how reels need to be picked up from pallets and then placed for further use, a various amount of lifting solutions can be used. Investing in reel lifting equipment optimised for your workflow significantly reduces work-related injuries and boosts efficiency and workforce flexibility.

This enables ergonomic, safe operations that maintain consistent productivity and allow anyone to handle heavy reels without downtime.

Reel lifting equipment: streamlining pallet to production handling

The packaging we see today, all started as a raw material or operating material, often in the rolled-up form of a reel as they are easy to store and move compared to sheets. Consumer demands for packaging are in a state of constant flux, with a growing emphasis on sustainability, durability, and aesthetic appeal. Beyond meeting these demands, packaging must also serve its primary function of safeguarding food from potential physical, chemical, microbiological, or other threats that could compromise food quality and safety.

The interplay between packaging material and food is subject to numerous factors. A well-considered choice of packaging material to prevent adverse effects on product quality, safety, and shelf life is needed. Factors such as flavour sensitivity, colour alterations, and microbial activity should be taken into account when selecting a product. The design of an effective food packaging system involves evaluating the type of polymer, preparation method, and the ratio of polymer content to food. This helps determine the degree of interaction between the food and the package.

Given the considerable thought invested in designing suitable food packaging, equal attention should be paid to the handling of the packaging itself.

Challenges of manual reel handling

Manually lifting and transporting reels can be both strenuous and difficult. Reels are often heavy, big and awkward to move, often meaning that workers are prone to strain-related injuries, accidents from obscured vision, or two workers needed to move one reel. In some cases, reels are too heavy and bulky for manual handling entirely.

Reel lifting equipment: the go-to solution

Reel lifting equipment helps alleviate physical strain on workers, makes two-person jobs become one and speeds up overall handling of reels whilst improving worker safety for improved productivity.

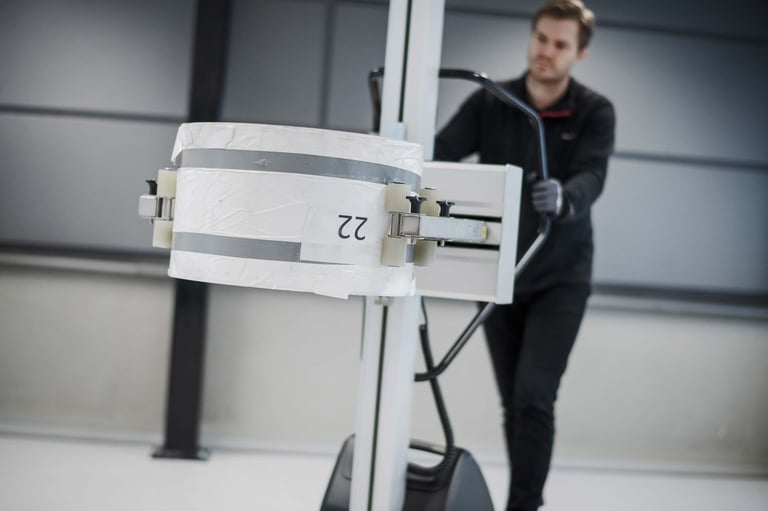

Lifting trolley

Depending on how the reels are picked up from pallets and placed for further use, a variety of lifting systems can be used. Lifting trolleys from TAWI offer versatile and flexible solutions for reel handling, with various options for picking up reels from pallets either from the core or from the outside. Due to their flexible and customer-oriented design, mobile reel lifters have adjustable legs that can be arranged to fit all kinds of pallets, making it possible for the operator to reach all reels stacked on the pallet.

Another major advantage of using lifting trolleys is their full mobility, enabling the operator to transport reels over large areas.

Beyond trolleys: Vacuum lifters and hoist

If lifting trolleys is not suitable for your operations, TAWI offers a range of other ergonomic reel lifting equipment. By using a vacuum lifter or hoist, reels can be picked up from pallets at high speed and easily placed for further use on a shelf, conveyor or other nearby area. These ceiling-mounted or column-mounted systems are optimal for lifting reels placed high up or in narrow spaces.

Investing in efficiency and safety

Using reel lifting equipment optimised for your workflow is an investment which will soon repay itself. Not only by minimising work-related injuries and health problems but also by increasing efficiency and workforce flexibility in your business.

By making sure the personnel can work ergonomically and safely, they can also maintain the same speed all day, every day, without tiring their bodies. It also becomes possible for anyone to lift and transport heavy reels which ensures that your operations never stand still.