Smart Lifting vs Full Automation: Finding the Balance in Manufacturing Efficiency

Flexible material handling is crucial for unlocking greater manufacturing efficiency, but in a world racing toward automation, choosing the right solution isn’t always straightforward.

As pressures mount to increase productivity, reduce costs and combat labor shortages, many production and plant managers are looking to automation. But full automation, such as robotic systems, isn’t always the correct answer. Whether it's due to space constraints, budget limitations, or the need for flexibility, there's a strong case to be made for innovative lifting solutions or semi automated equipment.

This article breaks down the pros and cons of both approaches, helping you make an informed decision that supports your team and your bottom line.

What Is the Difference Between Smart Lifting and Automation?

Let’s start with some quick definitions:

Smart Lifting (Semi Automated Equipment)

Smart lifting involves equipment such as vacuum lifters, hoists, or lift-assist devices that are operated by humans, but powered or assisted by automation. This approach combines the intuition of a human operator with the muscle of a machine, improving safety and efficiency, without entirely replacing the workforce.

Examples: TAWI vacuum lifters, lifting trolleys, mobile order-picking solutions.

Full Automation (Robotics)

Automation refers to systems that perform tasks independently, often with little to no human intervention. These include robotic arms, conveyors and automated guided vehicles (AGVs), typically programmed to handle repetitive, high-volume tasks.

Examples: Robotic palletizers, pick-and-place systems, CNC machinery.

Where Robots Shine

There’s a reason many manufacturers invest heavily in robotics. Here’s where they excel:

Precision & Repeatability

- Ideal for processes requiring consistent output.

- High accuracy with little deviation over time.

24/7 Operation

- Robots don’t take breaks, call in sick, or need vacations.

- Excellent for high-volume production environments.

Long-Term Labor Savings

- Once set up, they can operate with minimal oversight.

- Reduces long-term dependence on human labor.

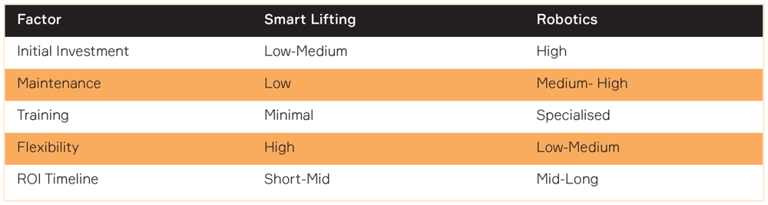

Cost Comparison: TCO & ROI

Where Smart Lifting Wins

Full automation may dominate headlines, but smart lifting often delivers more immediate and practical value, especially for small to mid-sized operations.

Flexibility

- Easily adapted to different product sizes, shapes and workflows.

- Can switch between tasks without lengthy reprogramming.

Lower Upfront Costs

- Significantly less capital investment than robotics.

- Fewer infrastructure changes are required.

Faster Implementation

- Minimal installation time.

- No complex programming or integration.

Supports Human Labor

- Reduces strain and injury, extending worker longevity.

- Especially valuable for ageing workforces or physically demanding roles.

The Hidden Costs of Robotics

If you’re still weighing whether to invest in full automation, consider a smart lifting solution. It's worth considering a few key factors that might help clarify the best fit for your operation.

Whilst automation offers clear benefits in some settings, it can also introduce hidden costs that don’t always show up in a spreadsheet. Robotic systems, for example, typically require dedicated floor space and safety zones. This is worth considering, as floor space is usually a valuable resource, and it could be better utilized by maximizing the production line. As is the way with any new machinery, full operational and maintenance training will be required. Repairs and reprogramming are time-consuming and costly, and complete reliance on machinery can exacerbate this. In addition to training, safety standards may require additional safeguards and documentation to ensure compliance.

Whilst there is an apparent shortage of labour in many sectors, fully automated systems can lead to the complete replacement of a valuable subset of the workforce, rather than building upon their existing strengths. This approach disregards the skill, experience, and adaptability of human workers, instead substituting them with machinery. Even if these employees are redeployed elsewhere within the organization, they often require extensive retraining, effectively erasing the value of their current expertise. The result can be devastating, not only for the affected workers but also for the broader organizational culture and morale.

Ultimately, the right solution depends on your specific production goals, workforce dynamics, and operational constraints. Understanding the trade-offs between automation and smart lifting can help ensure you make a confident, informed decision that balances performance with practicality.

Addressing Labor Challenges with Smart Lifting

Whilst full automation risks displacing skilled workers without leveraging their expertise, semi automated solutions like smart lifting offer a balanced approach, enhancing productivity without rendering human roles obsolete. Unlike fully robotic systems, which often ignore the adaptability of experienced workers, smart lifting empowers a broader workforce, including those with mobility restrictions or older employees who may no longer be in their physical prime.

By reducing the strain of heavy or repetitive tasks, these technologies not only minimize wear and tear on the body, preventing both immediate injuries and long-term occupational damage, but also create a more inclusive and flexible work environment. This approach preserves the value of existing skills while extending careers, attracting diverse talent, and maintaining morale, rather than eliminating jobs outright.

Case Study Highlight: Broman Logistics streamline operations with advanced automation and vacuum lifts.

“The vacuum lifter has been easy to use and all employees who have used it are positive,” - Elina Kuusipuska, Logistics Project Manager.

As a key logistics arm of the Broman Group, Broman Logistics recently expanded its operations and turned to TAWI to enhance efficiency and workplace ergonomics. To meet their needs, a TAWI vacuum lifter was installed and configured for use at two separate picking stations.

Due to the limited installation space, the solution needed to be lightweight, flexible and easy to integrate into an already busy environment. The TAWI vacuum lifter delivered on all fronts, simplifying material handling without disrupting operations.

Since its implementation, the vacuum lifter has significantly reduced physical strain on workers, enabling them to complete their shifts with more energy and less fatigue, thereby improving both productivity and employee well-being.

Smart Lifting as a Stepping Stone to Automation

Smart lifting doesn’t compete with automation; it complements it. For many companies, semi automated equipment serves as a bridge to full automation, offering:

- A way to prove ROI before larger investments

- Opportunities to optimize workflows before robot integration

- The ability to scale automation incrementally, reducing disruption

Q&A: What’s Right for Your Facility?

Q: Do I need full automation to improve productivity?

A: Not always. Smart lifting can deliver significant efficiency gains, especially in mixed-task environments.

Q: Is Smart Lifting the most significant temporary solution?

A: Not at all. It's a long-term investment in workforce wellbeing and operational flexibility.

Q: What’s the biggest advantage of smart lifting?

A: Its ability to enhance human capability without replacing it, improving safety, reducing fatigue and increasing throughput.

Q: Can I use both systems together?

A: Absolutely. Many facilities combine smart lifting with automation to get the best of both worlds.

Final Thoughts: It's About Balance, Not Binary Choices.

Automation isn’t all-or-nothing. The most innovative manufacturers are blending semi automated equipment with targeted automation to achieve the best results.

Whether you're facing staffing shortages, looking to improve safety, or exploring cost-effective upgrades, smart lifting offers a flexible, scalable path forward.

Ready to Lift Smarter?

Discover how TAWI’s flexible material handling solutions can help your team work safer, faster and smarter. Get in touch today.