Innovation in Food and Beverage Industry: Trends & Challenges in 2025

Innovation in food and beverage industry is driven by shifting consumer demands, technological disruption, and sustainability concerns. To stay competitive in 2025 and beyond, businesses must not only keep up with evolving food industry trends but also proactively address the challenges that come with change.

From supply chain transparency to labor shortages and sustainability pressures, the hurdles are real—but so are the opportunities for growth, innovation, and future-proofing operations.

Key Challenges Facing Food and Beverage Manufacturers in 2025

1. Supply Chain Transparency

Why it matters

Transparency isn’t just a buzzword—it’s become a business imperative. Today’s consumers demand to know exactly where their food comes from and how it’s made. Studies from Label Insights indicate that 94% of consumers say they’re more loyal to brands that practice full transparency. Regulatory bodies are also tightening the reins. Initiatives like the FDA’s Food Safety Modernization Act (FSMA) now require end-to-end traceability in food production, from raw materials to final products.

What’s the challenge?

Achieving true transparency requires major investment in advanced technologies like blockchain and IoT systems. These tools provide real-time tracking and verification, but integrating them into existing operations can be costly and complex—especially for small and medium-sized enterprises.

Opportunity for innovation in food and beverage industry

Adopting smart tracking systems and collaborative supply chain tools can not only improve compliance but also build lasting consumer trust—an invaluable asset in today’s market.

2. Labor Shortages

The root of the problem

The food and beverage industry is facing a severe labor crunch. Contributing factors include:

- An ageing workforce with fewer younger replacements

- Low unemployment creating competition for talent

- Pandemic-related disruptions and lingering safety concerns

In the UK, more than half of food and drink manufacturers still report chronic labor shortages, particularly for lower-skilled and seasonal roles.

The impact

Without enough staff, production slows down, delivery times increase, and costs rise. Companies often raise wages or offer incentives to attract workers, but this creates further financial strain and sometimes internal tensions among employees.

An innovative solution

Balancing automation with worker-centric technology is one of the most promising food industry trends. By introducing tools that assist workers rather than replace them, companies can improve productivity while retaining valuable human talent.

3. Sustainability Pressures

Why it’s critical

Sustainability is no longer optional. Climate change, geopolitical instability, and rising energy costs are reshaping food manufacturing at every level. The IPCC projects a 10–25% drop in crop yields by 2050 due to climate change—a wake-up call for the entire industry. At the same time, 73% of global consumers say they’re willing to change their consumption habits to reduce environmental impact. That’s a strong signal to manufacturers: sustainable practices are not just good ethics—they’re good business.

The challenge

Meeting these expectations often means overhauling production processes, sourcing eco-friendly materials, and investing in energy-efficient technologies—all of which come with upfront costs.

Where innovation comes in

Sustainability is now a driver of innovation in the food and beverage industry. Companies investing in clean technologies, renewable energy, and circular economy practices are not just adapting—they’re leading.

AI, Automation & the Future of Food Manufacturing

The buzz around AI and full automation is louder than ever—and for good reason. These technologies offer tremendous potential to transform the food and beverage industry.

Benefits of AI & Automation:

- Optimize production schedules

- Improve quality control

- Predict maintenance needs

- Cut operational costs by up to 30% (Deloitte)

- Reduce forecasting errors by 50% (McKinsey)

However, full automation isn’t always the answer. The costs of robotics, system integration, and ongoing maintenance can be prohibitive. There's also the risk of over-reliance on machines, which could lead to downtime or vulnerability during power outages or equipment failure.

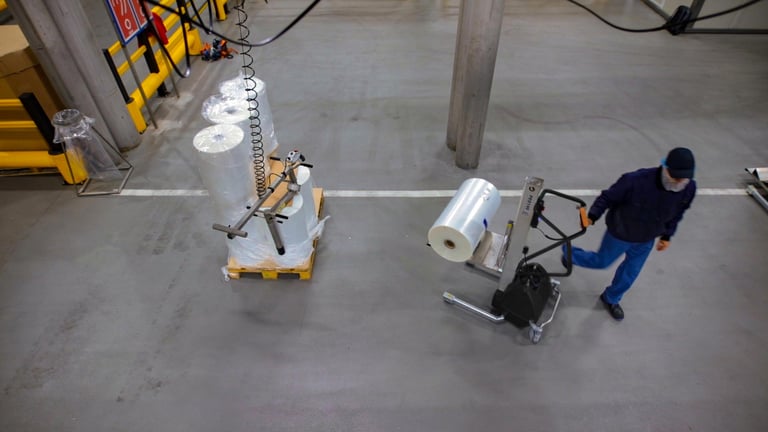

Smart Lifting: A Smarter Way Forward

At TAWI, we believe that the most resilient businesses combine people and technology. Our smart lifting solutions are designed to support—not replace—your workforce. By giving operators control over the equipment, we help improve safety, efficiency, and morale—without adding pressure on labor resources.

TAWI’s Smart Lifting Solutions Address:

- Health & safety regulations

- Labor shortages

- Fast delivery and increased demand

- Hygiene-sensitive environments

Built from durable stainless steel and designed for hygienic environments, our systems reduce physical strain, make two-person jobs manageable for one, and increase overall throughput.

Our Range of Smart Lifting Equipment:

- Vacuum Lifters & Mobile Vacuum Lifters

- Container Unloading Systems

- Portable Lifting Trolleys

- Crane Systems

- Hoists & Gripping Tools

Whether you're a large-scale producer or a mid-size manufacturer, our solutions are designed to scale with your operations and help future-proof your business.

Embrace Innovation in the Food and Beverage Industry

As we move through 2025, the innovation in food and beverage industry is not just about AI or robots—it’s about finding smarter, more balanced solutions to your biggest challenges. By investing in future-proof technology, like TAWI's smart lifting systems, you can improve operations, reduce risk, and strengthen your workforce—positioning your business to thrive in a competitive, fast-moving market.

Get in touch with us to explore how our solutions can help you stay ahead of the curve.