Ergonomic improvement at food producer Clarebout

Clarebout, the producer of pre-fried and frozen potato products, has invested in its employees' health and well-being.

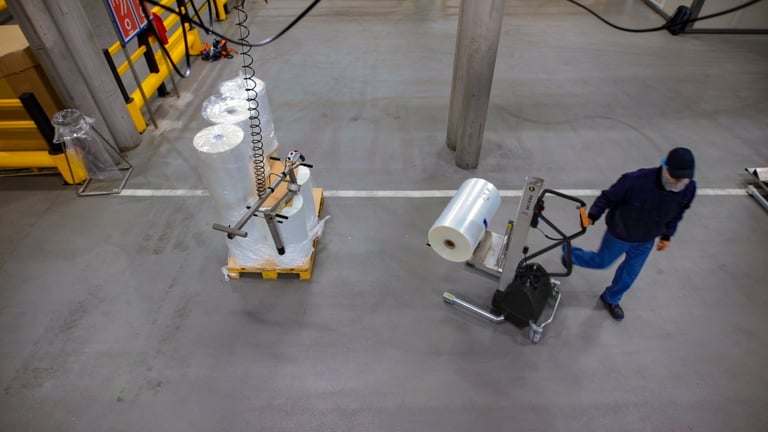

At its production site in Belgium, TAWI ergonomic lifting solutions are used at several workstations to handle big and heavy rolls. The lifting equipment allows one employee to lift 175 lb rolls from pallets and transport them into packaging machines without putting any harmful strain on their bodies.

One person can lift and transport 175 lb rolls effortlessly.

In the packaging process, Clarebout employees lift the large and heavy film rolls from pallets, stacked vertically in two layers. They tilt them from a vertical to a horizontal position and then transport the rolls to packaging machines where the fries are filled in bags, closed and sorted for further supply. 175 lb rolls are not easy to lift, tilt and transport in an ergonomic and time-efficient way, but TAWI lifting equipment has made this possible.

"175 lb rolls are not easy to lift, tilt and transport in an ergonomic and time-efficient way, but TAWI lifting equipment has made this possible."

Optimised workflow and ergonomics

Clarebout got a complete solution for handling rolls by combining different lift systems from TAWI. Ergonomically, safely and efficiently. To optimise the workflow, a hoist lift is used for lifting the rolls from pallets, tilting them and placing them horizontally on a lifting trolley. The lifting trolley is then used to transport and mount the rolls into the packaging machine. The two lift systems from TAWI work together seamlessly to ensure a time efficient and ergonomic work flow.

Click here to find about more about our Lifting Solutions for the Food Industry