Food and Beverage Lifting

TAWI provides customizable, hygienic lifting solutions for the food and beverage industry, enhancing safety, efficiency, and cleanliness in every stage, from incoming goods to palletizing. With lightweight, easy-to-clean vacuum lifters and trolleys, TAWI supports efficient handling of heavy items, reducing operator strain and contamination risks.

For the food and beverage industry, hygiene and safety are critical. Consumers trust that food and beverage manufacturers follow strict sanitary requirements and produce products to ensure no harmful substances make their way into the food or beverage. TAWI solutions can help guarantee maximum cleanliness and maximum efficiency for your operations.

It can be challenging to find employees strong enough to complete repetitive manual lifting tasks day after day. But a TAWI vacuum lifter or lifting trolley allows any operator, regardless of size or strength, to safely lift even the heaviest, most cumbersome bag, roll, or box.

Our products can be customized for your operation’s specific needs with our diverse array of suction feet for gripping different items and stainless steel options for areas with stringent sanitary standards. When you need to lift items safely, quickly, and hygienically, choose TAWI.

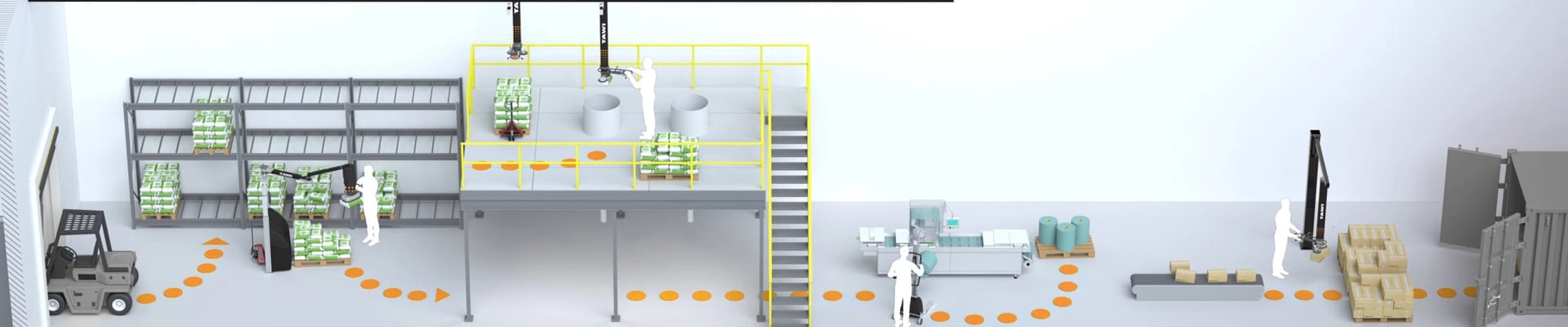

Smart lifting for every step of food and beverage operations

Incoming Food Products

Getting items from where they arrive to where they need to be can be a challenge in food and beverage manufacturing. Careless accidents or workplace injuries can happen when incoming goods are being transported. This damage to product or employee can cause slowdowns and a dangerous, inefficient environment.

With TAWI’s flexible vacuum lifting solutions, operators can have precise lifting and full control when moving materials, such as drums, kegs, barrels, and crates. The addition of a TAWI system to your operations will decrease operator’s fatigue and risk of injuries as well as increase productivity and efficiency. No matter what materials you are lifting in your manufacturing process, you can handle them safely, efficiently, and with a minimum of effort.

Food Processing

When processing food, operators work with raw ingredients. This increases the potential of contamination and makes adhering to all sanitary requirements even more important. Also, processing areas in facilities often operate in areas with low headroom of other structural challenges. The process flow is often “top down,” so a lifting system usually needs to be installed in as little a space as possible and close to the ceiling.

TAWI’s vacuum lifters and lifting trolleys meet the highest levels of sanitation and safety. We offer specific suction foot that can have direct contact with raw materials, such as meat and cheese, to safely lift them. Additionally, processing or emptying bags or sacks of ingredients is easier with a vacuum lifter handling the full weight of the load. TAWI’s products are easily cleaned and maintained with compact, flexible designs that means you can configure a system to work the way you need it to in the space you need it in.

Have questions?

Contact Us

Packaging and Palletizing

When packing or palletizing ingredients or raw materials for food and beverage manufacturing, any tears or holes in the bags or sacks could cause foreign substances to infiltrate the materials. Also, manually moving items to a pallet or mounting a reel to a packaging machine can cause injuries as people bend down or lift up heavy items.

A TAWI vacuum lifter can dramatically improve your workflow as operators quickly and delicately move, stack, or handle items without damaging the product or employees. The lift system is easy to operate and makes lifting and repositioning items like boxes, bags, or sacks during the palletizing process simple. Or when you need to move heavy and ungainly reels, TAWI’s lifting trolleys are strong enough to get the job down. Lifting and mounting reels on a machine axis is now a quick, safe process.

They trust you, You trust us

Your customers trust that your products are safe to eat, and you can trust us with creating a safe lifting environment for your employees. We have a long history of supplying lifting solutions to the food and beverage industry, so we have a deep understanding of how those operations can work more efficiently and productively.

Dugges Brewery in Sweden is a micro-brewery that knew they needed a solution for lifting their kegs above shoulder height, turning 90 degrees, and placing them on pallets. They bought a TAWI vacuum lift, and Mikael Dugge Engström, Founder and CEO of Dugges Brewery said, “The vacuum lifter has greatly improved our work environment since we have eliminated all heavy lifting of kegs.”

We’re not just a supplier, We’re a partner

TAWI partners with you to improve safety and efficiency in your operations all while meeting hygiene and safety standards. TAWI’s solutions are extremely lightweight, easy to use, and feature smooth, seamless surfaces that allow easy cleaning and only a minimum of particle accumulation. With low cost, low maintenance, increased safety, and increased productivity, TAWI’s products are a great return on investment.