Ampliqon Increases Batch Sizes with TAWI Customized Lifting Solutions

When Danish biotech manufacturer Ampliqon needed a way to safely handle larger bottles in a tight production space, they turned to TAWI. With a mobile electric lifter and customized gripping solution, the company can now load, lift, and mix heavy bottles effortlessly while protecting employees from strain.

The Company: Biotech Manufacturing at Scale

Ampliqon is a Danish producer of high-quality enzymes and laboratory reagents, widely used in hospitals, universities, research institutions, and life-science industries worldwide. At their Odense facility, production is carried out under strict hygiene standards. Bottled products are sterilized using autoclaving — a process that exposes them to high-pressure steam.

This process requires handling a variety of bottle sizes. Smaller bottles of 1,5 and 10 liters were manageable manually, but larger sizes presented significant challenges for both ergonomics and efficiency.

The Challenge: Heavier Bottles, Higher Demands

Ampliqon wanted to increase bottle sizes up to 30 liters in order to produce bigger batches and streamline production. However, manually lifting and loading such heavy bottles into autoclaves wasn’t feasible without risking employee health.

Another challenge was mixing. Several of Ampliqon’s products require thorough mixing directly in the bottles, a task previously done by hand. The company needed a solution that could both handle heavy loads and mix products safely and effectively, all within the facility’s limited production space.

The Solution: Customized TAWI Electric Lifter

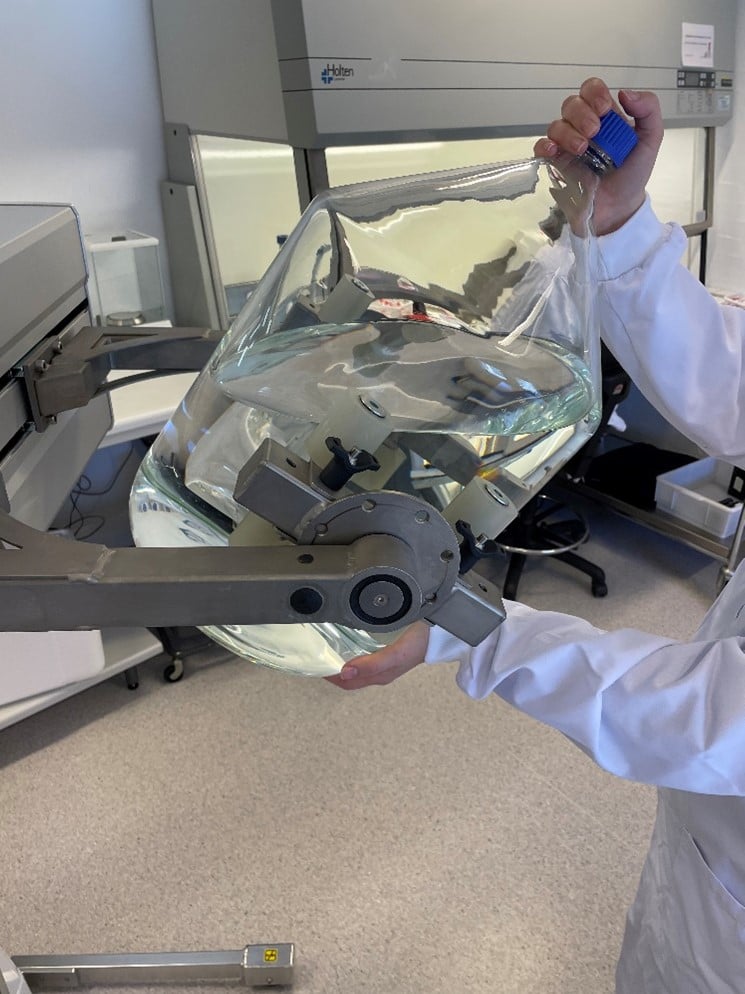

TAWI worked with Ampliqon to design a tailored solution using a mobile electric lifter equipped with a remote-controlled gripping mechanism. The device not only handles heavy bottles with ease but also allows full 360° rotation. This unique feature enables employees to mix products directly inside large bottles — without manual effort or strain.

“The electric gripping mechanism is remote controlled and can rotate 360°. This option for rotation allows us to effectively mix our bottles without putting a strain on our employees.”

– Carsten Mamsen Jessen, Molecular Biologist.

The Results: Larger Batches, Safer Staff

With the customized TAWI lifter, Ampliqon has achieved:

- Increased batch sizes: Bottle sizes expanded up to 30 liters, supporting larger production runs.

- Improved ergonomics: Heavy lifting and awkward manual mixing are replaced with safe, effortless handling.

- Space-efficient workflows: The compact, mobile lifter is well-suited for tight production areas.

As Carsten Mamsen Jessen explains:

“TAWI’s mobile electric lifter allows us to easily pick up bottles and move them between stations, while the gripping mechanism enabled an increase in bottle size up to 30 liters, thereby increasing our batch size.”

Look at our Stainless Lifting trolleys page for more information about these solutions.

Furthermore, we also have more ergonomic solutions for the pharma and Biomedical industry.