Pharmaceutical Industry Lifting

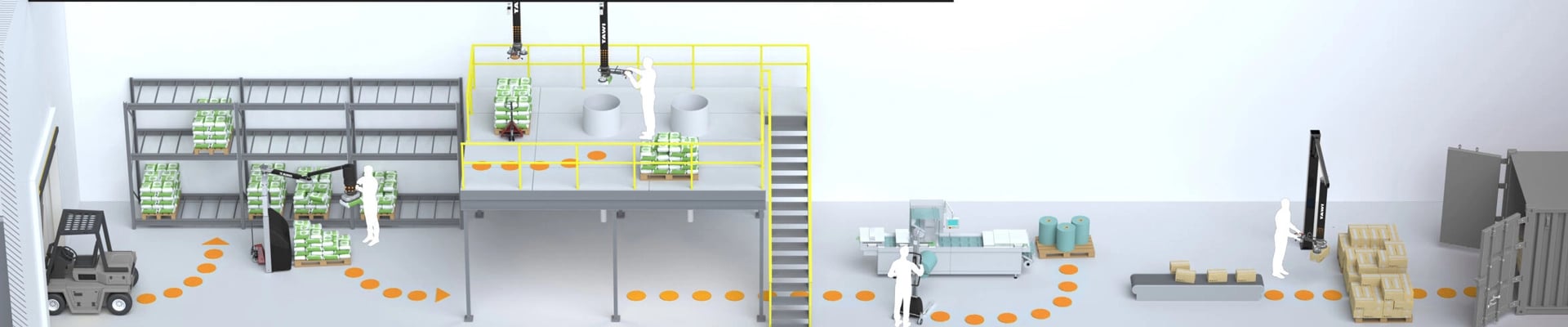

TAWI’s lifting solutions support the pharmaceutical industry by ensuring safe, ergonomic handling of sensitive materials in cleanroom environments, meeting strict sanitary standards and reducing operator strain. With customizable, lightweight, and easy-to-clean equipment, TAWI enables efficient and contamination-free lifting for tasks from weighing to palletizing.

Moving and handling the substances used in the pharmaceutical industry, especially sensitive organic material, requires great accuracy and safety throughout all stages of the process. Any tears or holes in the sacks can allow substances to leak out or air to reach the materials, rendering them useless. Also, these materials come in a wide range of packaging, such as barrels, sacks or jugs, and can cause work-related injuries from repetitive, manual lifting.

TAWI lifting equipment enables operators to lift these loads safely and securely, even when handling sacks or containers made of fragile materials like paper. For lifting in cleanroom and strict sanitary requirements, TAWI stainless steel lifts and trolleys are extremely lightweight and user-friendly, featuring smooth, seamless surfaces that make for easy cleaning and allow only a minimum of particle accumulation. So when you want safety and reliability without compromising sanitary requirements, use TAWI’s solutions for maximum operator protection and increased production efficiency.

Where can TAWI’s solutions help in pharmaceutical operations?

Pharmaceutical Weighing

The weighroom is the entry point to manufacturing and an important transition point for materials coming from a warehouse and entering the processing area. Employees must work with materials that come in a variety of shapes, sizes, and weights, and are at risk for intense physical strain and/or injuries from moving, lifting, and emptying ingredients. Well organized layout and choice of equipment will ensure a seamless, time-efficient, and safe weighing process.

TAWI’s stainless-steel vacuum lifters and trolleys facilitate safe and ergonomic pharmaceutical weighing, so weighroom staff can easily lift ungainly sacks and empty the ingredients into a pail, or drum placed on a platform floor scale. Thanks to their great flexibility, the same vacuum equipment can be used to lift a drum or pail from a scale onto a pallet, so it’s ready for transport into the processing area. Also, lifting trolleys can be hose-washed to prevent contamination and meet sanitary requirements.

Pharmaceutical Processing

Manufacturing of pharmaceuticals is a sensitive process, including the delicate handling of APIs and raw material that must not be contaminated. Employees are required to physically lift heavy sacks, drums, or other materials for manual material handling processes. And any equipment employees use in a cleanroom must generate minimal air contamination and be easy to clean.

To optimise pharmaceutical processing and relieve employees from heavy, repetitive manual handling, TAWI offers lifting solutions designed for use in cleanroom environments. With a vacuum lifter or mobile trolley, employees can easily move heavy, ungainly sacks without physical effort and empty them into a mixer in a safe, ergonomic manner. Drums can also be easily lifted, moved, turned, or tilted to help employees fulfil important job tasks without risking injury.

Have questions?

Contact Us

Pharmaceutical Palletizing

Every aspect of pharmaceutical production, including packaging, is tightly controlled and ruled by regulatory requirements. But mounting materials in packaging machines is difficult, cumbersome work. It poses a safety risk to the person lifting the material and a risk of slowing or stopping production if the materials aren’t swiftly put into the machine. To maintain an uninterrupted and dependable workflow, reliable handling equipment is a necessity.

TAWI’s lifting solutions make tasks, like loading reels into packaging machines, putting materials into boxes, or moving boxes from conveyer to pallet, easier and more efficient. Operators will no longer suffer physical strain from moving materials, and they can easily move materials to different parts of a facility with TAWI’s fully mobile equipment, ensuring time-efficient and cost-efficient operations.

Trusted Partner

Ampliqon is a Danish manufacturer of high-quality enzymes and laboratory reagents that operates in a manufacturing facility with strict hygiene requirements.

The electrical gripping mechanism is remote and can rotate 360 degrees. This option for rotation allows us to effectively mix our bottle without putting strain on our employees.

Carsten Mamsen Jessen, Ampliqon Molecular Biologist

Suited to Your Specific Operations

TAWI designs systems that fit your processes and specific needs. You can feel confident that your operations have an efficient workflow, optimized productivity, and increased safety when using our customizable equipment that can be fully mobile or installed on a crane system. Additionally, our cleanroom equipment solutions feature a hygienic, stainless steel design that works in areas where hygiene, cGMP’s, handling safety, and optimum ergonomic efficiency are essential.