Vacuum Lifters

Material Handling with Vacuum Lifters

TAWI vacuum lifters use vacuum power to grip and lift any load. Vacuum technology offers sustainable, safe and efficient handling of most types of goods.

- Time- and cost-efficient lifting.

- Safe grip without damaging the goods.

- Ergonomic and safe for the operator.

- Experinced vacuum lifter manufacturers.

TAWI vacuum lifters – for efficient everyday lifting

TAWI vacuum lifters are robust and reliable tools that make manual handling of loads safer and more efficient. No matter who you are or what you need to lift, TAWI vacuum lifters will make lifting efficient and effortless.

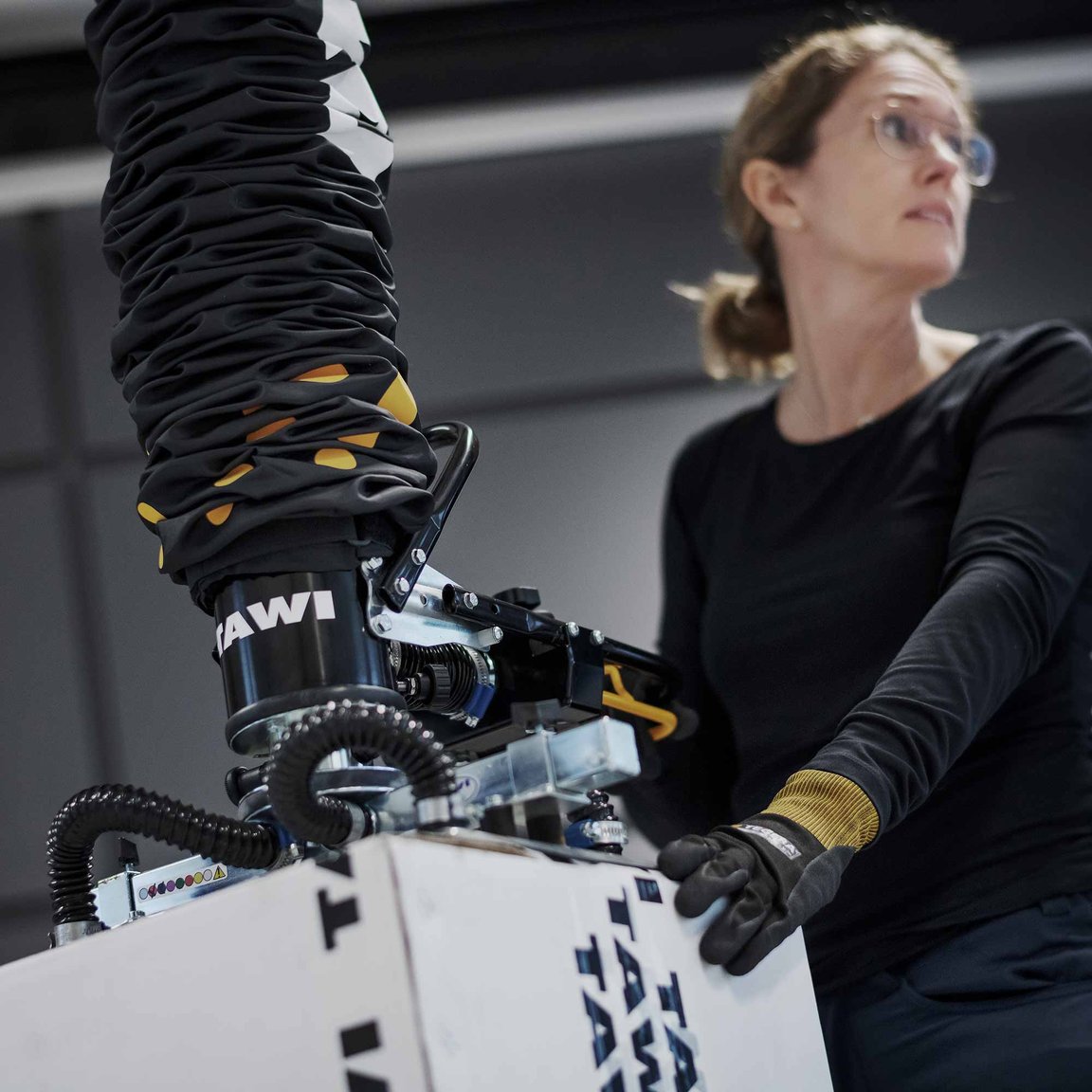

Ergonomic and user-friendly lifters

TAWI vacuum lifting systems are always designed with the user in focus. The lifters are so user-friendly anyone will learn how to use them within minutes. An ergonomic handle helps ensure a good working position for the operator and is just as comfortable for right-handed and left-handed users.

Safety for operator and goods

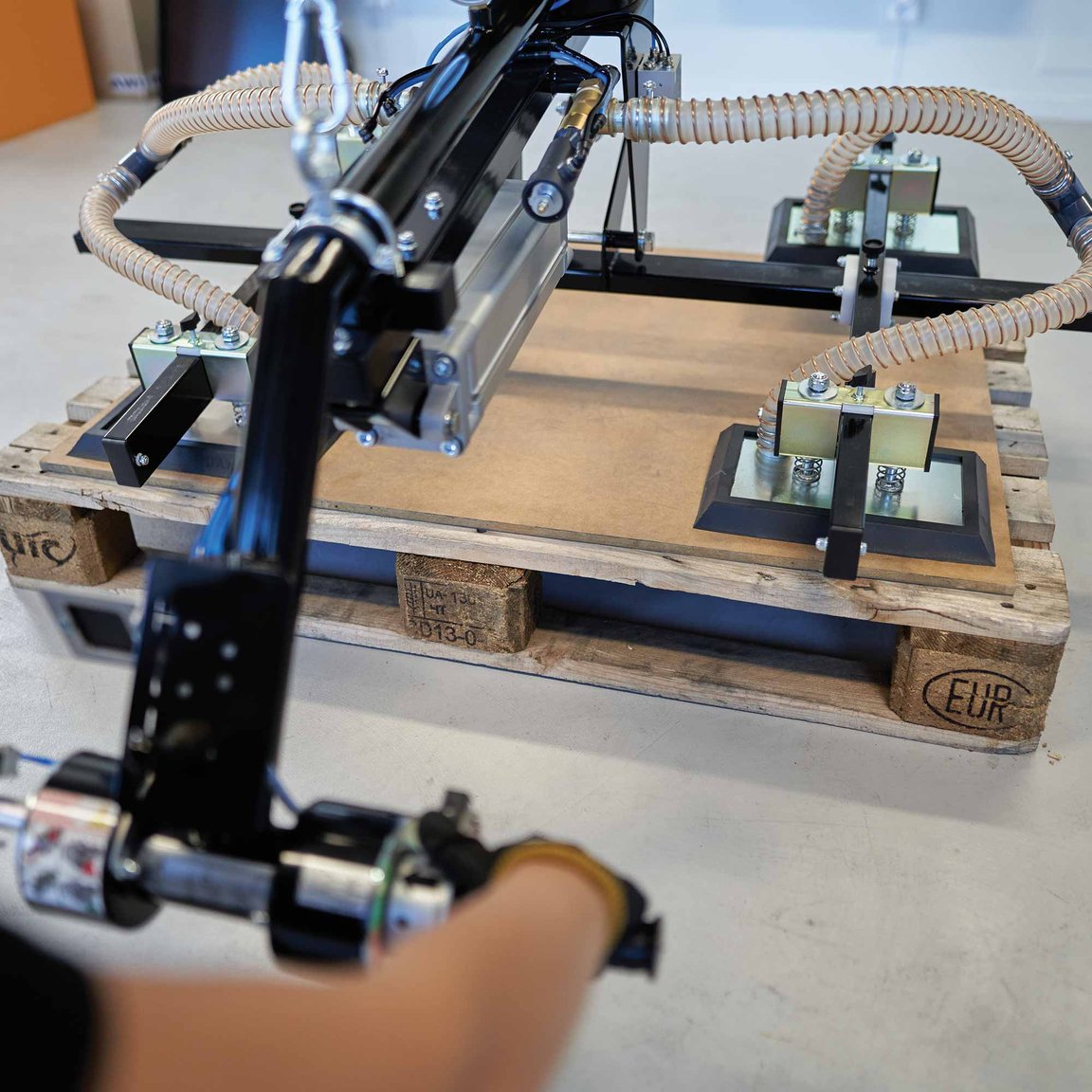

Vacuum technology is ideal for secure lifting without risk of damaging the goods or the person lifting them. Grip the load with suction cups designed for the goods you need to lift, regardless if you are lifting sacks, boxes, panels or something else. TAWI offers a wide selection of suction feet and we modify them to meet your specific requests if needed. All TAWI vacuum lifters can be modified for lifting in ATEX regulated facilities or cleanrooms.

Vacuum enables anyone to lift

TAWI vacuum lifters allow everyone to lift up to 270 kilos without effort. Giving everyone the power to lift increases workforce flexibility, making it easy for employees to switch between work stations. The vacuum lifting equipment is extremely versatile, handling everything from simple boxes to complicated car components. Add a quick coupling and you can easily use the same vacuum lift for more than one application, switching between different suction feet in no time. A flexible handle makes it easy to reach high without straining your back or shoulders. Flexible and efficient lifting for productive businesses.