Lifting Insights

Mehr bewegen mit weniger Kraftaufwand - TAWI FlexiGrip stellt sich vor

In den schnelllebigen Logistik- und Lagerumgebungen von heute ist Zeit ein kritischer Faktor, aber auch Sicherheit und Zuverlässigkeit. Hebesysteme müssen mit den Anforderungen moderner Arbeitsabläufe Schritt halten, insbesondere wenn die Lasten nicht immer perfekt ausgerichtet oder gleichmäßig gepackt sind. Deshalb haben wir den TAWI FlexiGrip entwickelt: einen neuen intelligenten Saugfuß, der für die Handhabung von Kartons mit hoher Geschwindigkeit konzipiert wurde.

Optimale Containerentladung mit der richtigen Ausrüstung

Das Entladen von Containern zählt zu den letzten arbeitsintensiven Bereichen der modernen Wirtschaft. Aufgrund der großen Bandbreite an Gütern und der beengten Platzverhältnisse im Container, sind das Be- und Entladen dieser großen Stahlkisten die einzigen Logistikprozesse, die nach wie vor von Hand ausgeführt werden.

Optimale Gesundheit und Sicherheit in der Lebensmittel- und Getränkeindustrie schaffen

Hebevorgänge sind ein wesentlicher Bestandteil der Lebensmittel- und Getränkeindustrie. Leider können sie auch eine der Hauptursachen für Verletzungen oder Fehlzeiten am Arbeitsplatz sein. Die Umsetzung von Arbeitsschutzmaßnahmen in der Lebensmittel- und Getränkeindustrie geht weit über die Einhaltung von staatlichen Normen und Gesetzen hinaus und hat erhebliche Auswirkungen auf Ihr Unternehmen.

Ausrüstung zur Containerentladung 2024: Eine vergleichende Analyse der besten technischen Lösungen

Im Jahr 2022 wurden weltweit mehr als 161 Milliarden Pakete verschickt. Bis 2027 wird ein weiterer enormer Anstieg auf 256 Milliarden Pakete erwartet, was ein Wachstum von insgesamt 59 % bedeutet. Die Aussicht auf ein Wachstum der Branche mag positiv erscheinen, aber für einzelne Unternehmen kann die Realität ganz anders aussehen.

5 Schritte zur Verbesserung der betrieblichen Effizienz in der Logistik

Angesichts von Herausforderungen, wie Arbeitskräftemangel und Sicherheitsrisiken, ist es mit den herkömmlichen Methoden in der Logistik nur schwer möglich, die Betriebseffizienz aufrechtzuerhalten. Der Einsatz von Technologien wie GPS-Ortung, Automatisierung und innovativen Vakuumhebern kann nicht nur die Betriebseffizienz steigern, sondern auch Kosten senken, die Sicherheit verbessern und eine hohe Kundenzufriedenheit gewährleisten.

Sind Vakuumheber überhaupt für mein Lebensmittel- oder Getränkeunternehmen geeignet?

„Die Unternehmen der Branche benötigen dringend eine Modernisierung, investieren aber tendenziell viel zu wenig in Technologie. […] anders als im B2C-Bereich haben diese B2B-Unternehmen mit einer veralteten Architektur und einem Sammelsurium verschiedener Prozesse zu kämpfen, was ihre Versuche behindert, ein profitables Wachstum zu erzielen.“ – Howard Doberman, Global Operations Transformation Leader bei Deloitte.

Die größten Probleme in der Logistik im Jahr 2025

Die Logistikbranche ist immer stärker mit dem wirtschaftlichen, politischen und ökologischen Zustand unserer Welt verflochten. Die Herausforderungen, denen sich diese Branche gegenüber sieht, sind nicht nur rein logistischer Natur, sondern spiegeln auch breitere gesellschaftliche Trends und Veränderungen wider. Dennoch müssen Probleme und Herausforderungen in der Logistik nicht zwangsläufig auch zu Problemen für Ihr Unternehmen führen.

Steht die Lagersicherheit im Widerspruch zu Produktivität und Effizienz?

Im Gegensatz zu einer weit verbreiteten Meinung schließen sich Sicherheit, Produktivität und Effizienz im Lagerbetrieb nicht gegenseitig aus. Tatsächlich können sie koexistieren und sich sogar gegenseitig verstärken. Wie wird das erreicht?

Trends bei Verpackungsmaterialien – wohin führt der Weg?

Verpackungsmaterialien sind ein elementarer Bestandteil der modernen Logistik, da sie nicht nur Produkte bei Transport und Lagerung schützen, sondern auch das Markenimage von Unternehmen repräsentieren. Das hat zu einer enormen Weiterentwicklung von Verpackungsmaterialien geführt. Die treibende Kraft sind technologische Fortschritte, sich ändernde Präferenzen der Konsumenten und Bedenken bezüglich der Nachhaltigkeit.

Sind Be- und Entladedienstleister heute noch eine kostengünstige Lösung für die Logistik?

Wenn Sie im Bereich Lieferketten tätig sind, dann ist Ihnen wahrscheinlich schon einmal der englische Begriff „Lumper“ begegnet. Für diejenigen, die es nicht wissen: Der Begriff „Lumping“, der in der Lkw-Branche verwendet wird, bezeichnet den Prozess des Be- und Entladens von Fracht durch andere Personen als den Versender, Empfänger oder Lkw-Fahrer selbst.

Die 3 häufigsten Arten von Verletzungen, die bei manueller Handhabung auftreten

Lagerhäuser sind geschäftige Orte, wo es von komplexen Maschinen, riesigen Produktstapeln und Mitarbeitern, die rund um die Uhr arbeiten, nur so wimmelt. Dieses dynamische Umfeld erhöht das Risiko von Unfällen am Arbeitsplatz und Verletzungen bei der manuellen Handhabung ganz erheblich.

Vergleich der besten Kommissionierer & LLOP-Produkte auf dem Markt

Die Auswahl des richtigen Kommissionierers und LLOP ist in der Logistikbranche ganz entscheidend für eine maximale Effizienz und Produktivität. Auf dem internationalen Markt ist eine Reihe von Kommissionierern erhältlich, die unterschiedliche betriebliche Anforderungen erfüllen.

Verbessern Sie „Pick & Pack“-Abläufe mit halbautomatischen Lösungen

Um den Anforderungen des modernen E-Commerce gerecht zu werden, ist es entscheidend, die Abläufe in der Kommissionierung zu optimieren.

Optimale Sortierung und Palettierung in Lager und Vertrieb

Das zunehmende Arbeitstempo beim Sortieren und Palettieren in den Lagern nach Covid-19 kann zu neuen Risiken für die Gesundheit und Sicherheit sowie zu einer erhöhten Fluktuation der Mitarbeiter aufgrund von Überlastung und Überarbeitung führen. Der Strom der Lastwagen und Container mit den auf Paletten gestapelten Produkten reißt nicht ab. Man muss also schnell und intelligent arbeiten. Aber können die Sortierung und Palettierung im Lager automatisiert werden, und falls ja, in welchem Ausmaß und zu welchen Kosten?

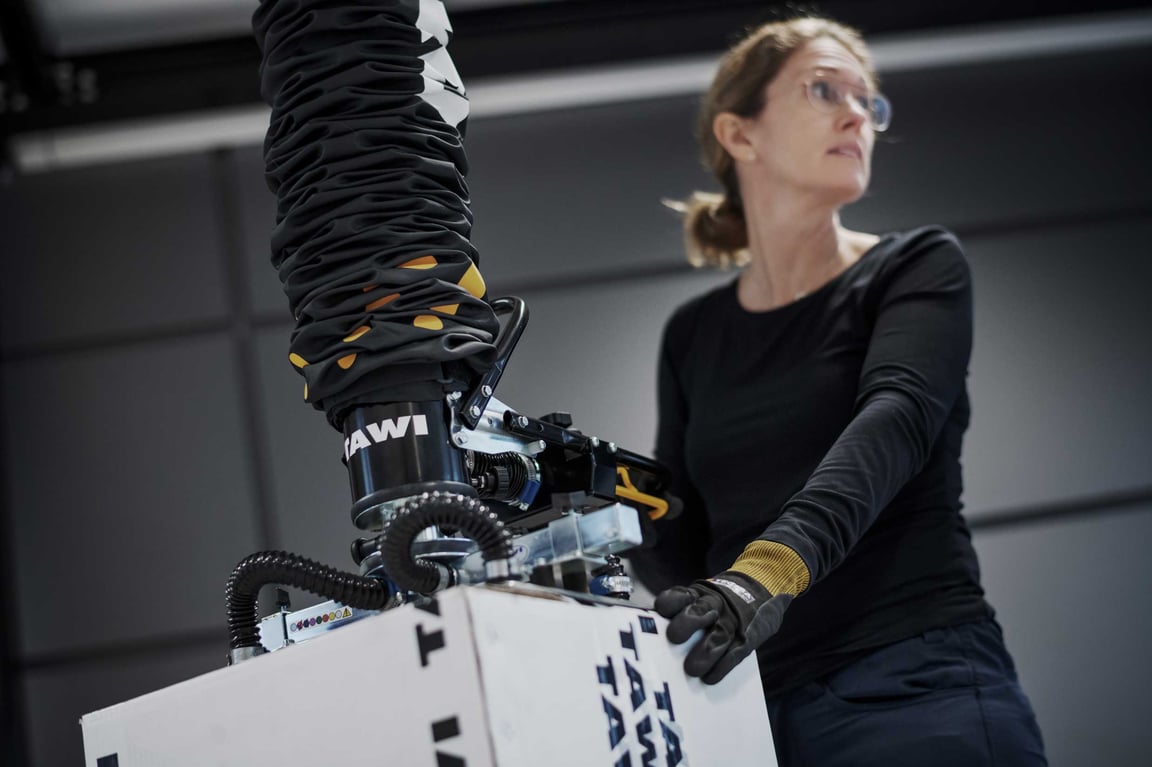

Mit TAWI Vakuumhebern die Arbeit in Ihrem Lager flexibel gestalten

Lager und Verteilerzentren stehen großen Herausforderungen gegenüber. Die Gründe dafür sind Personalknappheit und eine hohe Personalfluktuation, was zu mehr Überstunden und Personalproblemen führt. Flexible Arbeitskräfte können, unterstützt durch Vakuum-Hebetechnik, einen entscheidenden Unterschied ausmachen, um diese Herausforderungen zu meistern. Ein flexibles Personal kann die Gesamteffizienz steigern und den Betrieb Ihres Lagers effektiver gestalten.

Automatisieren Sie Ihren Materialumschlag in der Inbound-Logistik – und verschaffen Sie sich einen Wettbewerbsvorteil

Überall auf der Welt bereiten sich die Unternehmen darauf vor, den durch Covid ausgelösten Anstieg des E-Commerce zu bewältigen.

Die Herausforderung, sich der manuellen Handhabung in der Automobilindustrie zu stellen

Die Automobilherstellung umfasst viele verschiedene Arten von Arbeiten in einer Vielzahl von Sektoren und Industrien. Jede von ihnen, von der Komponentenbeschaffung und -herstellung bis hin zur Endmontage und dem Versand des Fahrzeugs, hat seine eigenen Herausforderungen. Eine Herausforderung für alle Branchen ist jedoch die manuelle Handhabung.

Steigern Sie die Produktivität am Arbeitsplatz mit (intelligenten) Hebegeräten

Wenn es ein Wort ist, das die heutige Arbeitssituation beschreibt, dann ist es BUSY. Fertigungs- und Logistikunternehmen suchen ständig nach Möglichkeiten, produktiver zu sein und mehr Arbeit in kürzerer Zeit zu erledigen. Diesem Bestreben nach, ist die manuelle Materialhandhabung ein häufiges, aber oft unbekanntes Erfolgshindernis.