Stål og Aluminium Profiler

Alsidige Kranprofiler

Aluminiumprofiler giver dig mulighed for at skabe et virkelig let kransystem. Stålprofiler muliggør længere brospænd og kan håndtere tungere belastninger. Kombinerede systemer er perfekte, når flere bjælker skal bære den samme belastning og giver den bedste samlede omkostning-ydelsesforhold.

- Aluminiumprofiler, når smidighed er prioriteret

- Aluminium er den mest omkostningseffektive løsning pr. kvadratmeter

- Stålprofiler muliggør længere brospænd

- Stålprofiler kan håndtere tungere belastninger

Hvad skal du løfte?

Hvornår skal man bruge stål- eller aluminiumprofiler?

TAWI rustfrie stålkraner er ideelle til håndtering indenfor fødevareforarbejdning samt kemi- og medicinalindustrien.

- Aluminiumprofiler giver nem manøvrering med minimal modstand.

- Rustfri stålprofiler anvendes, når hygiejne er i højsædet.

- Et kombinationssystem kan både sikre let og glidende håndtering af gods samt være dimensioneret til tunge belastninger.

- Kombinationssystemer kan tilpasses flere arbejdsstationer med forskellige behov.

- Materiale: Aluminium eller koldvalset stål

- Aluminium kapacitet: op til 125 kg

- Stål kapacitet: op til 1500 kg

Stål- og aluminiumprofiler – forskellige behov, forskellige metaller

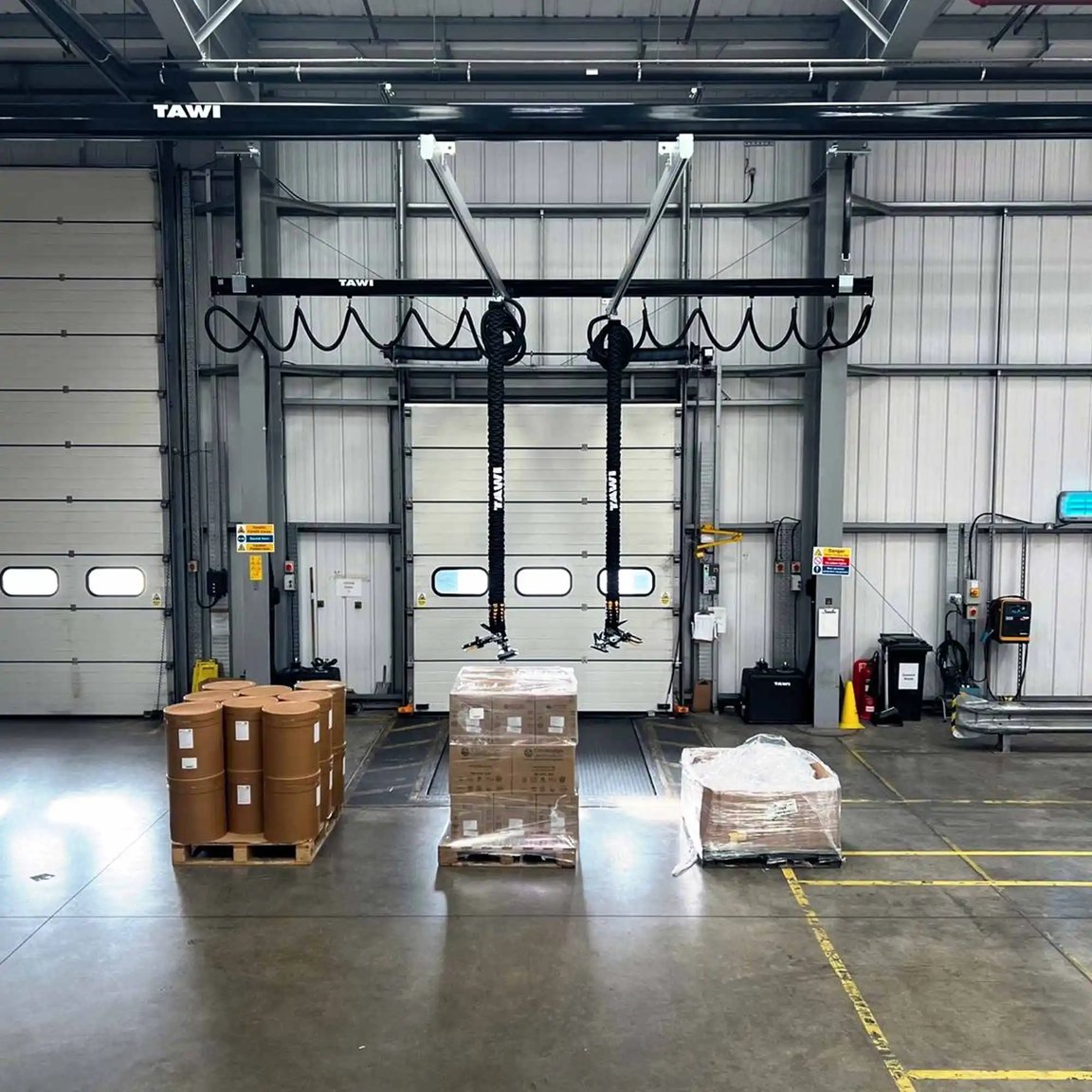

Vi leverer pålidelige kransystemer i aluminium, stål eller en kombination af begge. Altid tilpasset dine behov.

Aluminium er det foretrukne materiale til agile og virkelig lette kransystemer. Specialdesignede aluminiumprofiler sikrer den perfekte balance mellem styrke og vægt, så brugeren nemt og effektivt kan udføre sine arbejdsopgaver. Den lave egenvægt gør kransystemet ergonomisk og let at håndtere manuelt. Aluminium leveres i sin rå, naturlige form og er samtidig det mest omkostningseffektive valg til materialehåndtering af laster op til 125 kg.

Til tungere belastninger anbefales et system i højstyrket, koldvalset stål. Rustfrit stål er også et godt valg, når der stilles særligt høje hygiejnekrav, for eksempel ved håndtering af kemikalier, lægemidler eller fødevarer. Stålprofilerne kan spænde op til 8 meter mellem ophængningspunkterne, hvilket er en ideel løsning, hvis der er begrænsninger i tagkonstruktionen eller gulvarealet. Profilerne er lavet i ét stykke højstyrke, koldformet stål, hvilket giver et stærkt, omkostningseffektivt og relativt let kransystem. TAWIs fuldautomatiske pulverlakeringsproces sikrer en korrosionsbestandig overflade med en finish i høj kvalitet. Stålsystemerne leveres som standard i TAWIs sorte lakering, men kan tilpasses i farve, så de matcher dine eksisterende faciliteter og visuelle profil.

Hvis der ikke er særlige krav, der dikterer materialevalget, skal du blot fortælle os om dine behov, så designer vi et letvægts-kransystem med optimal ydeevne. Ofte bliver løsningen en kombination, hvor den bærende struktur er i stål, som kan bære flere aluminiumsløbevogne, der hver er dimensioneret til det specifikke materiale, der skal håndteres. Systemet er stabilt nok til at understøtte flere arbejdsstationer og samtidig dimensioneret til den tungeste belastning, men stadig let at manøvrere for operatørerne. Letvægts-kransystemet kan også kombineres med forskellige typer aluminium- og stålprofiler, så det passer til forskellige arbejdsstationer under samme kran. Løsningen kan nemt integreres i eksisterende arbejdsgange, og uanset konfiguration sikrer TAWIs patenterede letvægts-kransystemer en støjsvag, jævn og sikker drift, der giver det bedste arbejdsmiljø.

Kontakt os, så hjælper vi dig med at designe en løsning, der passer perfekt til dine driftsbehov.