Manual Lifting vs Smart Lifting in the Modern Workplace

From warehouses to factories, manual lifting safety remains important as ever, given that manual lifting is a part of daily operations. But behind every box lifted or load heaved is a hidden cost: injury, absenteeism and long-term health consequences for workers.

For Health & Safety Managers and Occupational Health professionals, the question is no longer if we need better lifting strategies, but how to implement them.

Enter smart lifting: ergonomic, tech-enhanced solutions like vacuum lifters that reduce physical strain whilst maintaining (or even improving) productivity. It allows you and your team to leverage lifting aids in the workplace without completely changing how you work. Let’s explore how smart lifting compares with traditional manual handling and why it’s time to modernise our approach.

What Is Manual Lifting?

Manual lifting involves using the body to lift, lower, carry, push or pull objects, often without mechanical assistance. These tasks are widespread in logistics, warehousing, construction, healthcare, food production and countless other sectors.

Common manual lifting tasks include:

- Lifting boxes, containers, or tools

- Transferring products from pallets to conveyors

- Moving large or awkwardly shaped items

- Stocking shelves or organizing storage

Whilst these tasks may seem simple, their cumulative impact is far from it.

The Cost of Ignoring Manual Lifting Safety Techniques

Manual lifting is a leading cause of musculoskeletal disorders (MSDs), which affect the muscles, joints, tendons and nerves, particularly in the back, shoulders and arms.

Key Health Risks:

- Back strain and slipped discs

- Shoulder and rotator cuff injuries

- Joint degeneration over time

- Repetitive strain injuries (RSIs)

These conditions don't just cause pain; they can also lead to permanent disability, loss of income, and significant employer costs. This is what makes taking manual lifting safety seriously all the more important.

Learn more by reading “The 3 most common types of manual handling injuries”.

The Stats: Why Manual Lifting Safety Matters

Data from global safety bodies underscores the urgent need to address health and safety in manual lifting.

According to HSE (UK):

- 0.5 million workers suffering from work-related musculoskeletal disorders (new or long-standing) in 2023/24.

- Over 4.1 million working days were lost due to such injuries.

What Is Smart Lifting?

Smart lifting refers to the use of ergonomic technology, such as TAWI vacuum lifters, to assist or automate the lifting process. In short, it is introducing lifting aids in the workplace. These systems are designed to minimise the physical effort required by workers while enhancing precision and speed, all while enhancing health and safety in manual lifting.

Smart Lifting Tools Include:

- Vacuum lifters: Use suction power to lift heavy loads effortlessly.

- Hoists and cranes: Mechanically move large or awkward items.

- Trolley systems and conveyors: Reduce manual handling distances.

The Benefits of Ergonomic Lifting Equipment

Smart lifting isn’t just about tech. It’s about creating a healthier, more sustainable workforce.

- Worker Wellbeing - Reduced strain means less fatigue, fewer injuries, and higher job satisfaction.

- Reduced Sick Leave - Fewer injuries mean lower absenteeism and reduced compensation claims.

- Inclusive Workplaces - Ergonomic aids allow older workers, women and those with physical limitations to perform lifting tasks safely, supporting diversity and longer careers.

- Improved Productivity - TAWI lifting systems streamline workflows, leading to faster, safer and more accurate handling.

- Ergonomics as a Form of Sustainability - We often think of sustainability in environmental terms, but workforce sustainability is just as critical. A workplace that protects its people is a workplace that retains talent, reduces turnover and avoids costly injuries.

Implementing smart lifting not only increases manual lifting safety but is a proactive step toward ESG (Environmental, Social and Governance) goals, ensuring health, equity and safety remain at the heart of operations.

But don’t just take our word for it…

"When I contacted TAWI, they were brilliant," says Kajal, Health & Safety Environmental Coordinator at Cranswick Convenience Foods. "They visited our site, reviewed the operation, and designed a trolley tailored exactly to our needs. It’s battery-powered and simple to use—it’s made a big difference for the whole team."

Read how TAWI solutions have benefited companies up and down the country, from the food and beverage sector & cold chain logistics to baggage and boxes via our case study page.

Q&A: What Health & Safety Managers Want to Know

Q: Aren’t lifting aids expensive?

A: Although there is an upfront investment, the ROI is clear. Reduced injuries, insurance claims and downtime mean long-term savings.

Q: Will lifting technology slow down production?

A: Quite the opposite. TAWI systems are designed for seamless integration and often speed up workflows through better ergonomics and fewer delays.

Q: How do we know which lifting aid is right for us?

A: TAWI provides expert consultation based on your environment, load types and workflow needs, ensuring the right fit for your business.

The Bottom Line: It’s Time to Lift Smarter

Manual lifting may be common, but that doesn’t make it safe or sustainable. Smart lifting technology—like TAWI vacuum lifters—empowers businesses to safeguard their workers, streamline operations and foster inclusive, long-term careers.

For Health & Safety professionals, the message is clear: modern lifting isn’t a luxury, it’s a necessity.

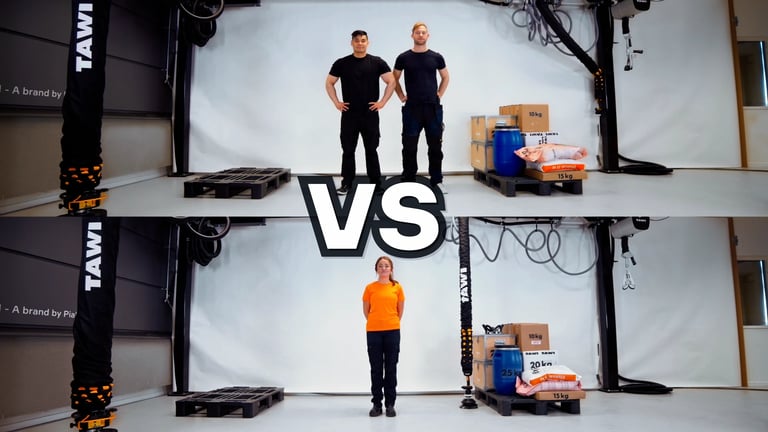

See smart lifting vs manual lifting in practice: