Chemical Industry Lifting

TAWI provides vacuum and trolley solutions designed to safely lift and handle chemical products, minimizing risks like contamination, injury, and exposure to hazardous materials. With options like stainless-steel lifters for clean rooms and ATEX-certified solutions for flammable environments, TAWI enables efficient, safe, and ergonomic lifting across chemical operations, from filling to palletizing.

Speak to our experts

Working with chemical products means working with potentially hazardous or flammable materials – materials that can result in serious consequences if improperly handled. Thus, safety and reliability for handling different materials are critical for your employees and your business.

TAWI provides both vacuum and trolley solutions that offer a range of adaptions to ensure you can handle any lifting or moving challenge with ease. Our stainless-steel solutions support lifting materials in clean room or meticulously controlled environments while our industry-leading ATEX solutions can be used in flammable or explosive environments. With operators using a TAWI lifting solution to get the job done, you can minimize the possibility of accidents, contamination, or exposure to toxic materials, and run your operations safely and profitably.

Solutions for Each Stage of Chemical Operations

Filling and Weighing

When filling or weighing chemical ingredients or components, there are several challenges. It’s critical that nothing compromises the packaging or process to avoid contamination. Also, it’s important that no accidents or faulty handling can occur, so that no dangerous chemicals leak into the environment. Finally, employees can suffer injuries from the repetitive strain of manually lifting heavy items.

TAWI solutions can serve as the cornerstone of a highly safe and accurate filling and weighing system. With a TAWI vacuum lifter or trolley, chemical operations can maintain the highest hygiene standards and dust control while also ensuring maximum efficiency and product containment. Operators can easily lift, hold, turn, tilt, or rotate a variety of materials, such as drums, sacks, and bags, for high accuracy and safety.

Chemical Processing

The materials used in the chemical industry usually reach the factory in paper or plastic sacks and bags (sometimes in barrel or jugs). Often quite heavy and easily torn, these bags and sacks are difficult to lift and manipulate in an ergonomic fashion. Lifting these heavy bags and emptying the contents can be challenging even with two people working together, and it carries a high risk of product contamination.

However, a TAWI vacuum lifter means a single person can lift heavy items with minimal effort or risk of contamination. The task of lifting a bag from a pallet to a mixing container and the emptying and mixing ingredients can now be completed by one person faster, safer, and more efficiently.

Have questions?

Contact Us

Chemical Palletizing

In the past, palletizing has usually been a manual and very labor-intensive process. This has resulted in frequent repetitive stress injuries, downtimes, and damage to products or ingredients. In addition, chemical products are highly combustible, making it even more risky to handle these products.

TAWI stainless steel lifters and trolleys and ATEX certified solutions ensure ergonomic and safe palletizing of any chemical product. Any employee, regardless of strength, can quickly pack or palletize heavy boxes and containers more efficiently, which leads to greater workplace diversity and flexibility. With equipment that’s easy to use, install, and maintain, TAWI is the partner you need to achieve optimum lifting for your operations and your bottom line.

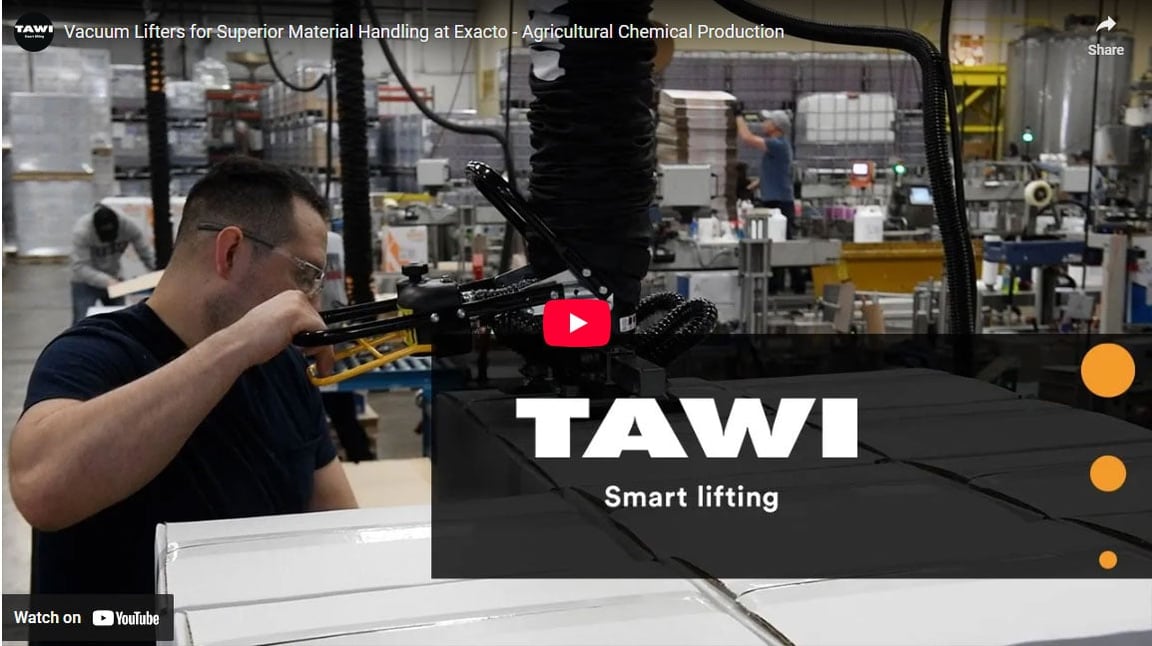

It has been a blessing. By the end of the day, we are not even near half way burned out like we used to be before TAWI was installed.

Joe Greenlee, Exacto Production Cell Leader

Improve Your Chemical Operations

TAWI’s expert consultants will help guide you in setting up a customized solution designed for your specific needs and your specific company. Contact us to start talking with an expert today.