Steel and Aluminum Profiles

Versatile Crane Profiles

Aluminum profiles let you create a truly lightweight crane system. Steel profiles enable longer bridge spans and accommodate heavier loads. Combined systems are perfect when multiple girders will weigh down the same system, and enable the best overall cost-performance ratio.

- Aluminum profiles when agility is prioritized

- Aluminum is the most cost effective solution per square meter

- Steel profiles enable longer bridge spans

- Steel profiles accommodate heavier loads

What We Can Lift

When to use steel or aluminum profiles

TAWI stainless steel cranes are ideal for the food processing, chemicals and pharmaceutical industries.

- Aluminum profiles offer easy maneuvering with little resistance

- Stainless steel profiles when sanitation is prioritized

- A combination system can both smoothly maneuver goods and be sized for heavy loads

- Combination systems can suit several workstations of different needs

- Material: aluminum or Cold rolled steel

- Aluminum capacity: <275 lbs

- Steel capacity: <3300 lbs

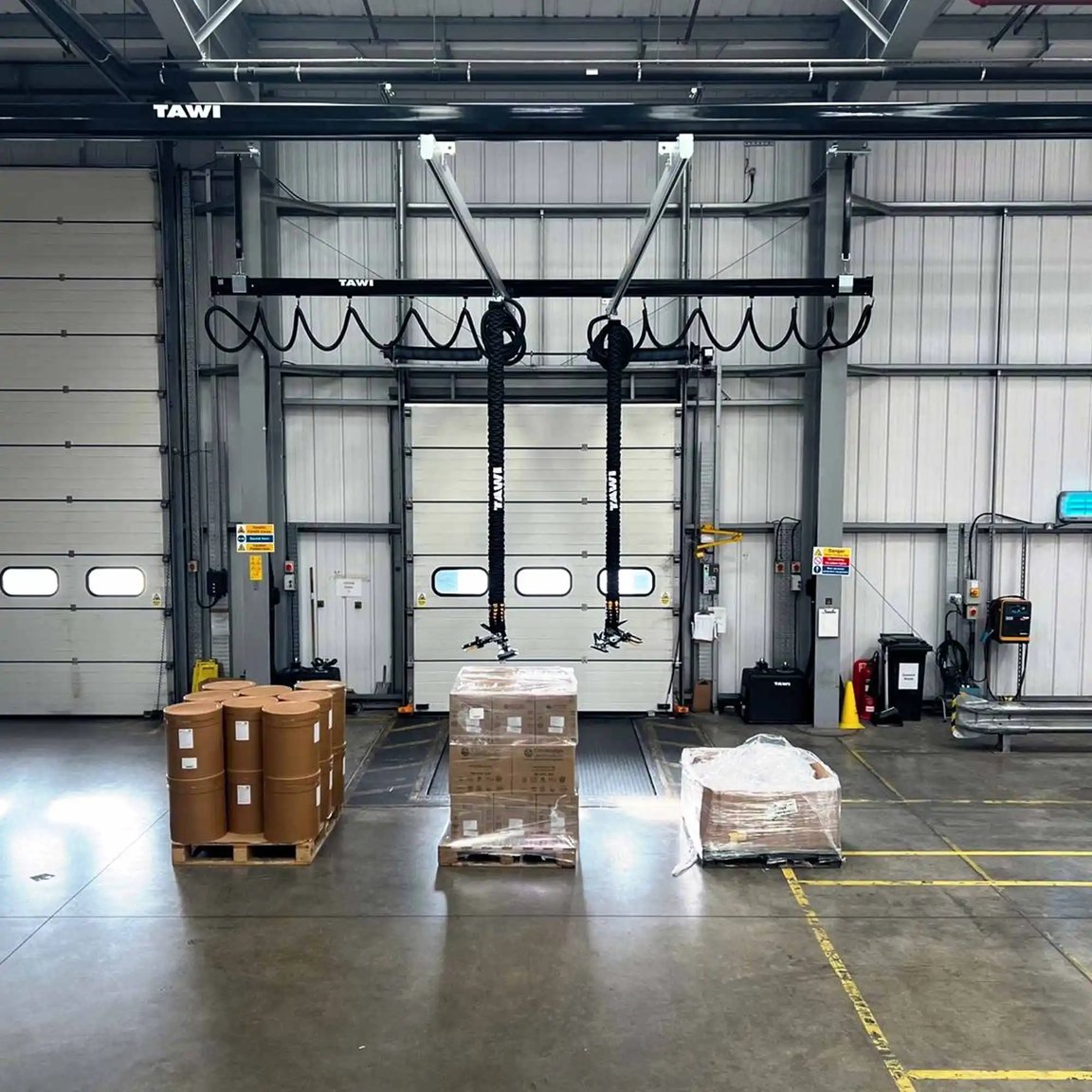

Steel and aluminum profiles - different needs, different metals

Offering reliable crane systems made of aluminum, steel or both. Always customized to meet your every need.

For agile and truly lightweight crane systems – aluminum is primarily the material of choice. Engineered aluminum profiles ensure a high strength to weight ratio in order for the user to carry out the operations with ease. The resulting low self-weight of the lightweight crane system contributes to ergonomic manual handling for the operator. Aluminum comes in its raw, natural appearance and is also the most cost-effective alternative for material handling of loads of up to 275 lbs.

For heavier loads, your system should be engineered from high strength, cold-rolled steel. Stainless steel is also appropriate when the operations have high sanitary requirements such as when handling chemicals, pharmaceuticals or food items. The steel profiles can handle up to 8 meters between the suspension points, a perfect solution if the roof structure, or floor area, has spatial limitations or structural constraints. The steel profiles are made from a single piece of high strength cold forming steel, which provides a strong and cost-effective product, as well as resulting in a relatively lightweight crane system. TAWI´s fully automated powder coating line provides corrosion resistance thanks to top quality finishing. Steel systems come standard in the TAWI black lacer but can be custom colored to fit your already established operations and branding profile.

If there is no outer factor that weighs in on the preference of material, just tell us the needs of your intended operations and we will custom design a light weight crane system of optimal performance. Such a solution is many times a combined system where the supporting structure is made from steel in order to carry several lifting girders made from aluminium, in turn dimensioned for the material being handled. The system is then structurally stable to hold several work stations and dimensioned for the heaviest handled load yet easily maneuvered by each operator. The lightweight crane system can also be combined in terms of which type of aluminum and steel profiles are being used, to suit different types of work stations separately under the same girder system. The solution is easily integrated into existing operations and whatever the configuration, TAWIs patented lightweight crane systems always provides quiet, smooth and safe operation, guaranteeing the best working environment.

Contact us and we can design a solution that optimally fits your operational requirements.